STIFFNESS VS. STRENGTH

Firstly, we should differentiate between the strength of a beam, and the stiffness of a beam.

Bending strength is the amount of stress required to break the beam.

Bending stiffness on the other hand, is the amount a beam will deflect under a given load. The higher the stiffness, the less deflection that will occur.

Since a large proportion of timber engineering design is governed by deflection, the stiffness of beam is often critical to the design and is the focus of this Blog.

Anytime an engineer designs a beam, they must consider:

#1 The Material Properties

and

#2 The Section Properties

#1 - MATERIAL PROPERTIES

In basic terms, the material property just refers to what the stuff is made of… A beam made with a stronger, stiffer material will result a beam that is stronger and stiffer!

In terms of stiffness, the material property measured is called “Youngs Modulus of Elasticity”. This is commonly referred to as the material “MOE” or “E-value”. A materials’ MOE is determined by testing carried out at timber mills or at engineered wood product manufacturing facilities and is measured in Gigapascals (GPa).

Some examples of timber MOE value are:

- GL8 glue-laminated timber, which has an E value of 8.0GPa.

- MGP10 pine, which has an E value of 10GPa.

- Wesbeam e-beam+[F17] LVL or “E14 LVL”, which has an E value of 14.0GPa.

Bending stiffness is proportional to the E value. A beam with a 40% higher E value for example will have a 40% high stiffness for beams of the same size.

e.g. a 190x45 e-beam+[F17] E14 LVL will have a 40% higher stiffness than a 190x45 MGP10 beam, since 14.0GPa / 10.0GPa = 140%

#2 - SECTION PROPERTIES

So… if one timber product has a higher E value than another, it must be stiffer, right? Well, that’s only half the story!

The section property, which is the second part of the equation, basically refers to how big the beam is. A beam that is bigger, taller, and wider, will be stronger and stiffer!

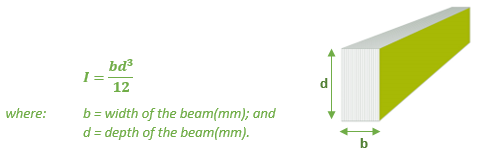

In technical terms, the sections property is known as the “Moment of Inertia”, or I value. For a rectangular beam, the formula for the I value is defined by the equation below:

If comparing two beams of the same height, the width of the beam will be proportional to the I value and overall beam stiffness. In other words, the wider the beam, the stiffer it will be and the less it will deflect!

e.g. a 63mm wide beam would be 9% stiffer than a 58mm wide beam of the same Material, since 63mm / 58mm = 109%

WHAT DOES THIS MEAN FOR MY DESIGN?

In summary, the stiffness of a beam can’t just be determined by its’ E value. The size of the beam, including the width of the beam, is equally important and must also be considered.

If you would like any further information regarding the design of timber beams, or to find out the different sizes and grades of Wesbeam LVL available, feel free to contact the Wesbeam Tech Hotline on 1300 356 460.