Members of Wesbeam’s technical and sales staff were lucky enough to attend a seminar hosted by Timber Insight on 19 June 2019 at Burswood WA.

Renowned timber engineer Jon Shanks, Associate Director of TimberED, presented his discussion at the seminar, titled “Designing to Embrace Prefabrication Opportunities – Advances in Prefabricated Building Systems”.

Prefabrication can be anything from nailing frames together before delivering to site, to fully enclosed panels, to completed modular structures.

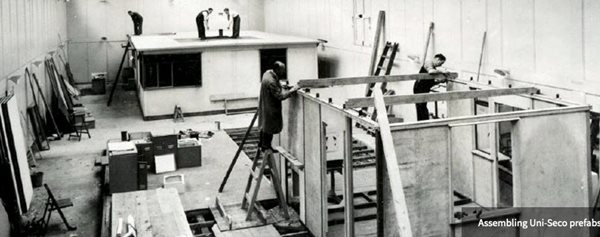

The presentation demonstrated not only the level of prefabrication available to the market today, but also the long history of prefabrication in timber structures around the world.

Figures 1-4 below were provided by Jon Shanks after his presentation and show examples of modular prefabrication, both historic and modern.

Figure 1: Post World War 2 prefabrication of structural modules.

(Source: www.prefabmuseum.uk)

Figure 2: Installation of prefabricated modular structures.

(Source: Getty Images)

Figure 3: Prefabrication of panels and modular structures.

(Source: Jon Shanks, 2019)

Figure 4: Installation of prefabricated modular structures.

(Source: Jon Shanks, 2019)

Whilst the practices around ethical and safe installation procedures have certainly changed, the concept around modular construction has been well understood for a long period of time.

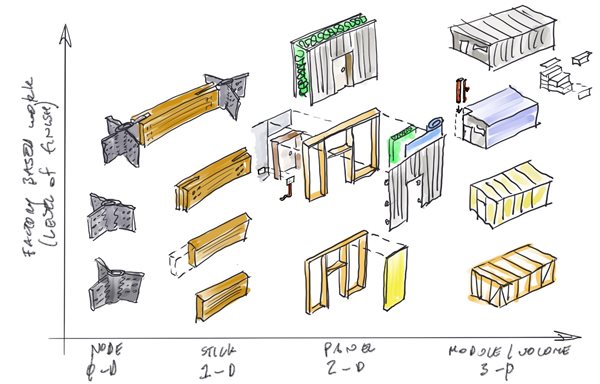

The question that Jon raised to the audience was “How much to prefabricate?”

The graphic below in Figure 5 demonstrates the extents of prefabrication, from simple node and stick connections, to fully enclosed panels, to modular construction.

Figure 5: Scales of prefabrication.

(Source: Jon Shanks, 2019)

Modular construction suits certain project types, where single occupancy room sizes suits transportation. However, it requires a large amount of space for prefabrication and transport. Stick building on site can present issues with time, efficiency and quality control, especially as timber framed structures get bigger.

Prefabrication of structural panels is currently offering a solution to the timber framing sector that combines the quality control of prefabrication, with efficiencies in the installation that are not present in a stick build. The extent to which the panels are prefabricated should be carefully considered for each project in consultation with the supply chain for an efficient and optimum solution.

Wesbeam is currently working with various industry stakeholders in the design of panelised components, including floor panels using e-joist floor joists, and wall panels using e-beam LVL.

To learn more about TimberED and the consulting services they provide in the timber engineering field, contact:

Jon Shanks

Associate Director, TimberED

jonshanks@timbered.com.au