Wesbeam is responsible for all the operations and manufacturing of our LVL I-Joists. Essentially the production line is a mixture of four different saw systems together with a gluing system. In this blog, we walk you through our joist production line to show you how we produce our LVL I-Joists for delivery across Australia.

Components of LVL I-Joists

The flange material of our joists is made using LVL manufactured at our Neerabup LVL manufacturing plant in Western Australia. The middle of the I-Joist has a web made from Oriented Strand Board. Read our blog on the LVL manufacturing process to see how LVL is made.

I-Joist Flange Groove Creation

Each of the flanges that are used to make a joist is ripped into two sections from a single stick. This creates two identical sections for the top and the bottom flanges. At the same time, a groove is ripped into the flange as it comes through our first saw called the Rex saw.

The Rex saw is very critical in the process as it splits the flange in half. It rips the groove very accurately to create an exact mating match to the web further down the process. We use diamond tip cutters to get a very precise finish to our groove.

Cutting the Joist Web

The next two saws in the process are both involved with the web production. The first saw rips the web into smaller sheets. The sheets come in at 2.4 meters long, so we rip them down into smaller sections to be the right size to use through the middle of the joist depending on the height of the joists that we’re producing.

Joist Web Profiling

From there, we go to our next saw along the production line. This saw profiles the web to match exactly the profiling that we have put into the flange. This is a critical profile with an angle that must precisely match the angle of the groove in the LVL flange. We also use diamond tip cutters on these saws. We measure the critical angles to confirm that the flange and web will match perfectly.

Glue Application

The next part of the LVL I-Joist process involves applying glue to the web flange joint. The glue used is a mixture of resin and a hardener. The hardener allows the resin to cure quickly. The head of the glue gun system inserts glue into the flange grooves. Glue application is a critically controlled part of the joist manufacturing process.

I-Joist Assembly & Cutting to Size

Once we have our glue in the flange groove we then slide the web into it. Using a squeezer system we then slowly close the LVL flange down over the web. From there we move to the last saw used in the I-Joist production line. A flying saw is used to cut the LVL I-Joist to the lengths required.

Once it comes out of the flying saw the I-Joist goes into the nester for a short period for the glue to cure. The I-Joists are then stacked together, wrapped, packed and shipped around Australia.

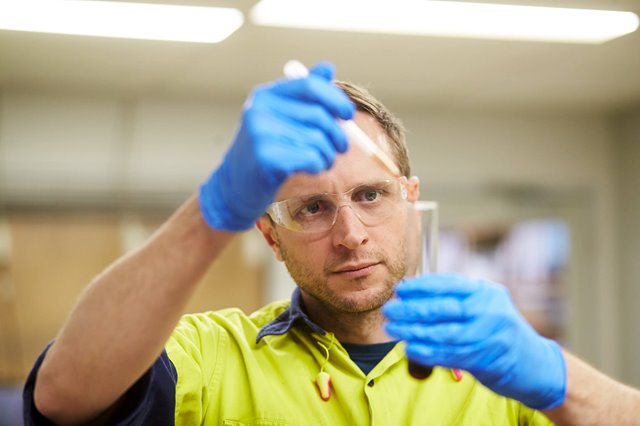

Our Quality Control Process

We have a tight quality control process that runs throughout our factory. Every step has control measures that are taken continuously while manufacturing. Measurements of angles, grooves, depths, glue curing times, volumes of glue, and glue temperatures are constantly monitored throughout the process and reported in our quality control system. These are further analysed by our laboratory to ensure that we are constantly delivering a structurally sound product.

This manufacturing process is what gives Wesbeam LVL I-Joists their high strength and versatility. The final product is a strong yet lightweight floor joist that is used for constructing timber floor systems. Wesbeam can make an excess of a million linear meters of joists a month for the Australian markets.

Contact our Sales Support today to discuss how you can secure your Australian I-Joist supply today.