What is embodied energy?

Embodied energy is the total amount of energy consumed for the construction of a building. The embodied energy is the total of the energy required to mine/harvest, manufacture, transport and erect the product at the construction stage.

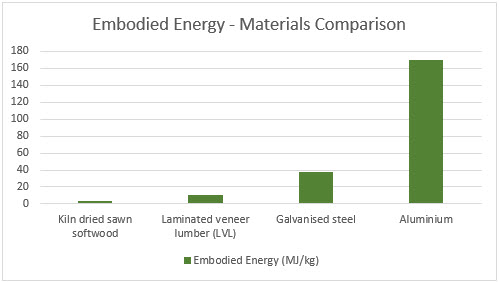

Embodied energy is typically defined for different construction materials, or different finished structures. Embodied energy is measured in Mega Joules (MJ), either by weight for construction materials (MJ/kg) or by area for finished structures (MJ/m2).

The higher the embodied energy, the more energy required to take the product from its origins (mining or harvesting) to a finished product (construction and maintenance), and therefore the higher impact it has on the environment.

Comparing embodied energy

By comparing the embodied energy of construction materials or construction systems, you can identify the likely environmental impacts that the material or system will impose.

This allows designers, architects, builders and stakeholders that are committed to sustainable and green building practices to choose their construction materials accordingly.

Because the embodied energy also includes the energy required for transportation, using locally sourced and Australian made building materials, such as Wesbeam LVL, will also reduce the environmental impact of the building.

Timber as a construction material

It has been long known that timber is the green building material of choice. Not only does timber provide benefits for cost, weight and constructability on site, it also has a naturally low embodied energy when compared to other building materials.

The graph below1 shows the embodied energy required by commonly used building materials:

Timber in a construction system

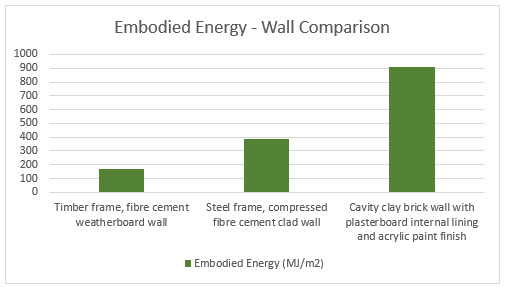

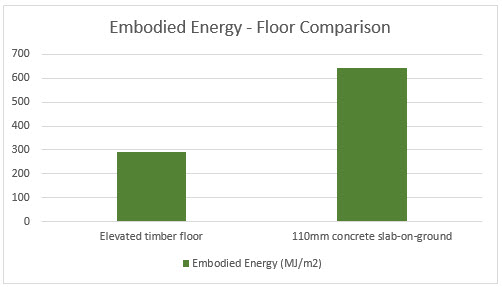

Whilst comparing the raw materials used in construction is a good way of determining the likely environmental impacts at the early stages of consideration, comparing common construction systems will often be carried out to account for the differences in material weight, and how the material is used as a finished component.

The graphs below1 compare assembled construction systems that are commonly used in the Australian construction industry.

Wesbeam LVL

Wesbeam LVL is a locally grown and locally manufactured Engineered Wood Product (EWP). Aside from its excellent structural properties, the use of Australian made LVL in timber construction systems that often include sawn timber and other EWP has significant environmental benefits, as demonstrated by the Embodied Energy Comparison.

To learn more about the benefits of using Wesbeam LVL, follow the link below.

VIEW BENEFITS OF LVL

Written By Tom Rickerby, Wesbeam Structural Engineer

GRAPH DATA SOURCE:

1. Lawson, B. 1996. Building materials, energy and the environment: towards ecologically sustainable development. Royal Australian Institute of Architects, Red Hill, ACT